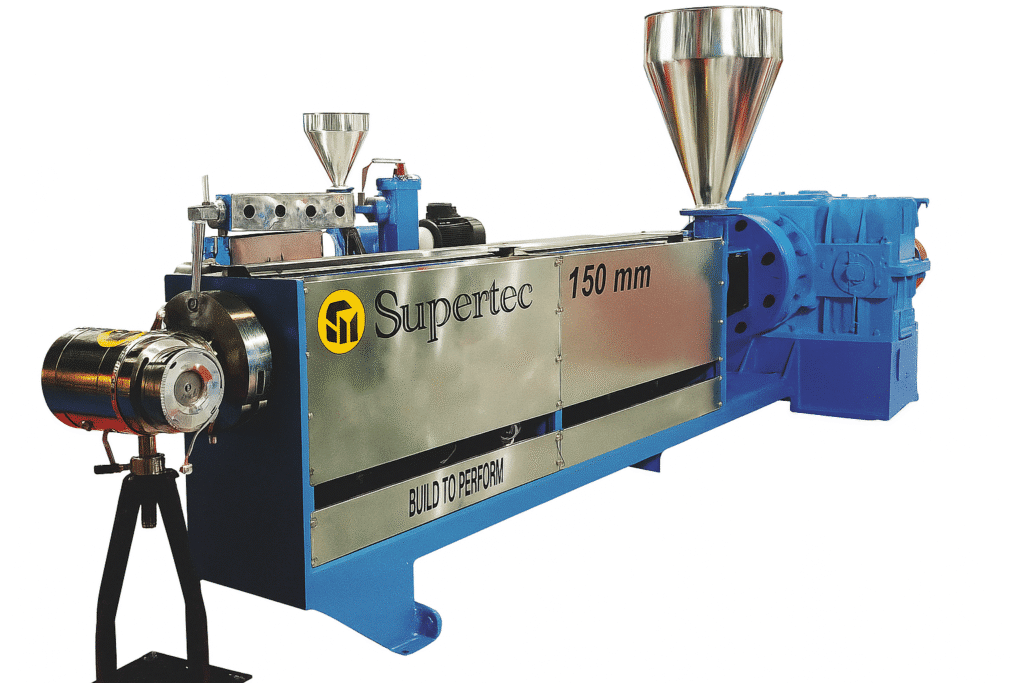

EXTRUDERS

As a leading manufacturer of rubber cable extrusion machines in India, the latest generation of Supertec Machines’ rubber extrusion lines is engineered to meet the evolving demands of LSZH, HFFR, and XLPE cable extrusion. These advanced systems integrate energy-efficient torque motors that enhance productivity and precision in EV charging cable extrusion lines, polyethylene extrusion lines, and the automation or retrofitting of existing extrusion systems. Each machine is equipped with high-torque gearboxes, ensuring superior performance and reliability while processing modern materials.

The screw and barrel geometry has been developed through decades of Supertec Machines’ extensive experience in the extrusion industry and its in-depth understanding of polymer behavior. The extruder features a modular, high-torque helical gearbox, designed to deliver exceptional torque and durability. Depending on specific process requirements, the system is equipped with either a splash-cooling or forced-cooling lubrication setup—ensuring efficient operation, long life, and minimal maintenance.

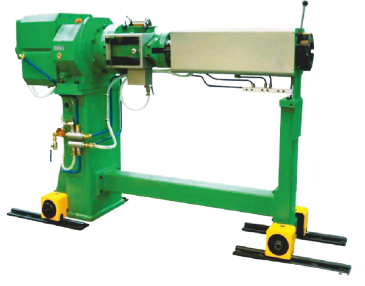

Silicone Extruders

Mechanical Characteristics

- Robust reducer with integrated AC motors.

- Cylinder and endless screw and shirt made of bimetallic material.

- Water cooling in the gearbox, motors, cylinder, endless screw and feed zone

Electrical Equipment

- AC motors are integrated into the gear unit.

- Digital frequency inverter for AC motors.

Mechanical Characteristics

- Data cables insulation lines.

- Building wires insulation lines.

- Automotive cables insulation lines.

- Combined lines.

- Sheathing lines.

- Tandem filling and sheathing lines.

- Fluorinated products insulation line.

- Silicone insulation lines.

- XLPE insulation lines.

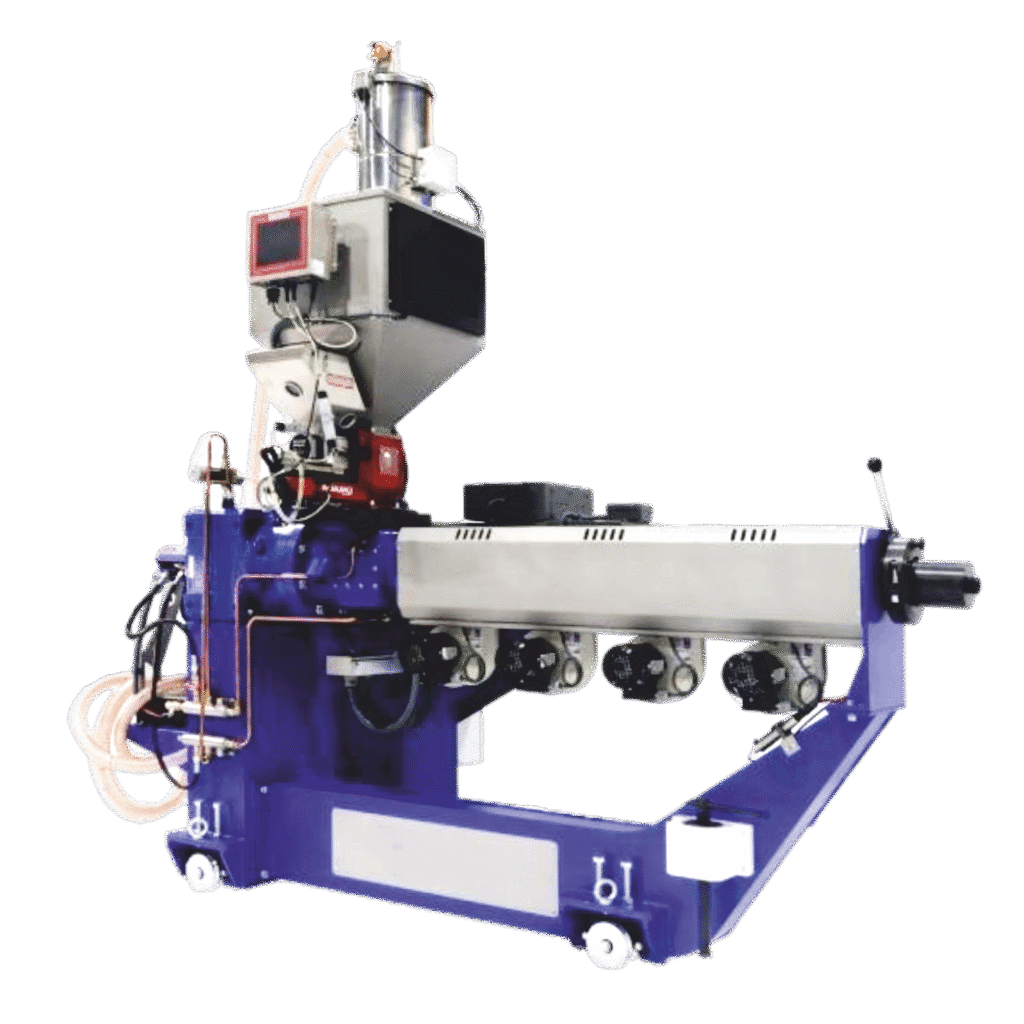

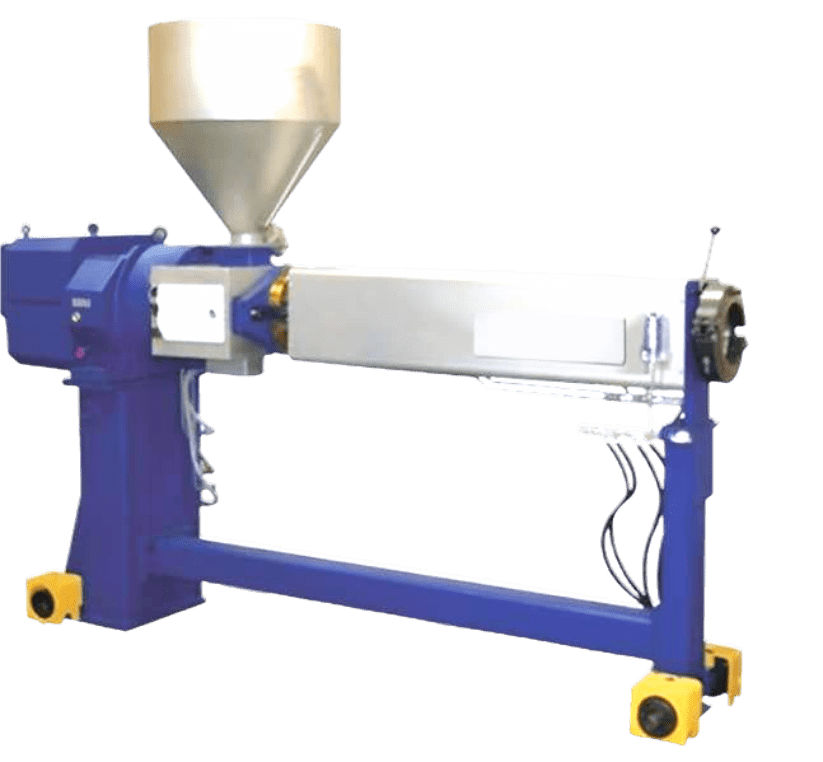

Rubbers Extruders

Mechanical Characteristics

- Robust reducer with integrated AC motors.

- Cylinder and endless screw and shirt made of bimetallic material.

- Water cooling in the gearbox, motors, cylinder, endless screw and feed zone

Electrical Equipment

- AC motors are integrated into the gear unit.

- Digital frequency inverter for AC motors.

- Main extruders diameter from 80 mm to 160 mm; auxiliary extruders diameter from 35 mm to 80 mm

- Tandem extrusion or co-extrusion process can be used to produce cables with filler

- Cooling Trough with or without thermoregulation and final section composed of single / double trough and return pulleys