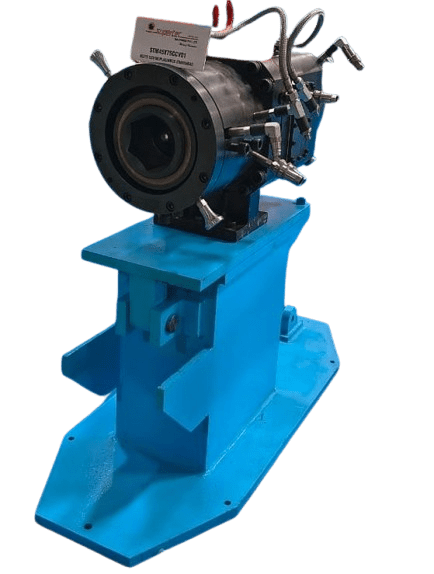

Crossheads and Tooling

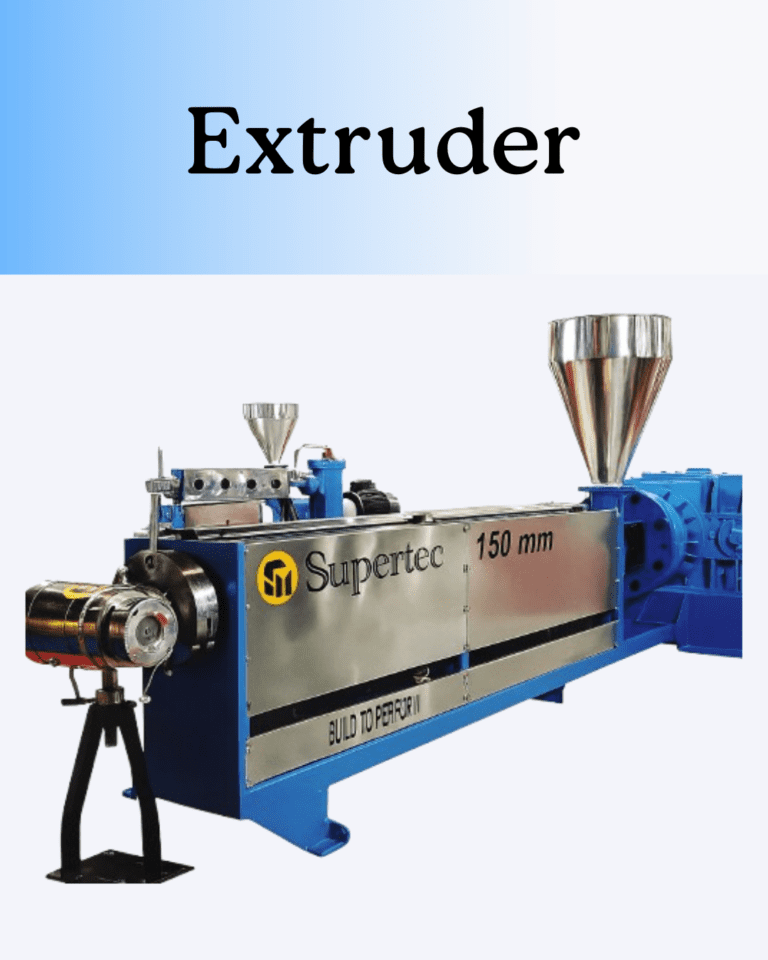

Our high performance extrusion crossheads cover all applications for wire and cable production.

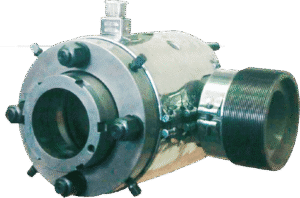

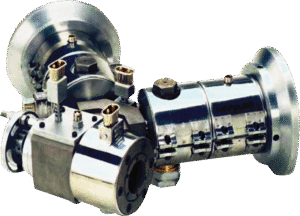

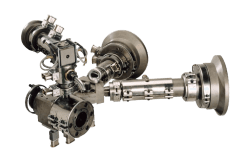

Supertec Machines has introduced a new series of Extrusion CrossHeads, designed with a compact structure to ensure precise and uniform distribution of extruded material over the conductor. This advanced series is engineered for insulation and sheathing applications of round, sector-shaped, and multi-core cables.The range includes multiple models such as Fixed Centering, Manual Centering, Single Cross Head, Dual Cross Head, and Triple CrossHeads, each built to deliver superior performance and long-lasting reliability in cable extrusion processes.

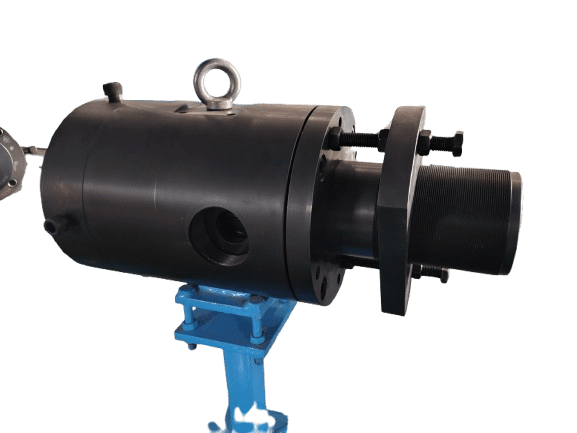

The in-house manufacturing capabilities at Supertec Machines Pvt. Ltd. allow us to achieve exceptional precision in the machining of cross head components, ensuring our customers receive a product perfectly suited to their specific applications. Each cross head part is crafted from high-grade alloy steel and undergoes vacuum heat treatment for enhanced durability and performance.

At the heart of every cross head lies its melt distributor, responsible for uniformly channeling molten polymers around the conductor. To meet the evolving demands of modern materials such as PVC, Nylon, XLPE, ZHFR, and FRLS, Supertec Machines designs and optimizes various melt distributor profiles using advanced computer-aided software.

Multiple crossheads

Different Type of Crossheads

Manual Centering Heads Sizes : 10-12 to 130-150

Self-Centering Heads For Big Diameters Sizes : upto 80-100

Triple Extrusion Head Size : 4/6 to 35/45mm

Supertec Machines Pvt. Ltd. manufactures a comprehensive range of high-precision extrusion crossheads engineered to ensure uniform material flow, excellent concentricity, and consistent insulation quality in wire and cable production. Our advanced crossheads range includes 140/160 dual layer crosshead, 35/45 dual layer crosshead, 100/120 dual layer crosshead, 80/100 dual layer crosshead, 40/60 dual layer crosshead, and 25/35 dual layer crosshead, each designed to meet specific processing requirements across a wide variety of wire and cable extrusion applications.

These extrusion crossheads are developed using optimized melt flow geometry to support smooth processing of materials such as PVC, XLPE, FRLS, and other specialized compounds. Built with robust construction and precision machining, our crossheads deliver long-term durability, reduced material wastage, and stable performance at high production speeds. With a focus on reliability and efficiency, Supertec Machines’ extrusion crossheads help manufacturers achieve superior product quality, improved operational consistency, and enhanced productivity in modern cable manufacturing operations.

Request a Quote Today

Reach Us

Location :

Khasra No-205/437, Mahalaxmi Temple, Ballabhgarh-Sohna Rd, near Radha Sowami Ghar, Faridabad, Pali, Haryana 121005

Email :

vishalgupta2902@gmail.com

info@supertecmachines.in

Phone :

+91 8595423093

+91 9654723093