Cable and wire extruder line. How it is work ?

Cable and wire extruder line - Manufacturers

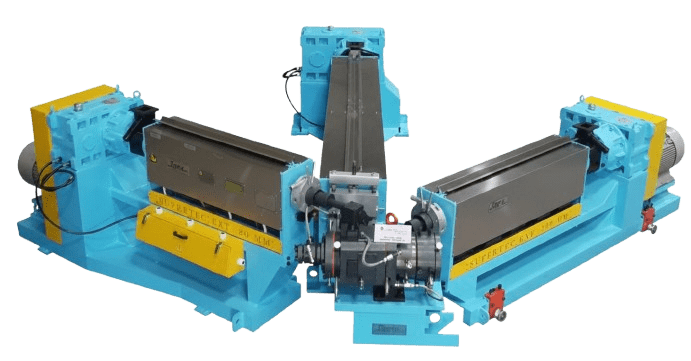

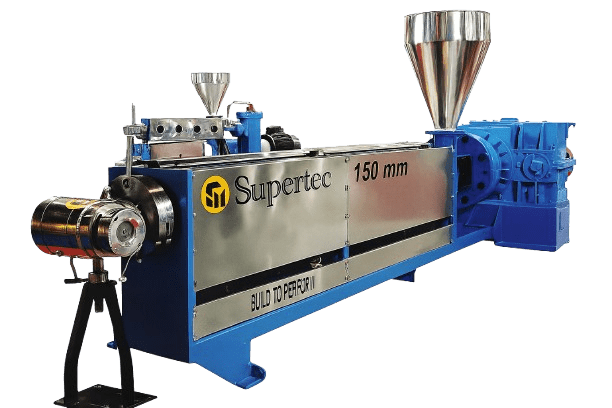

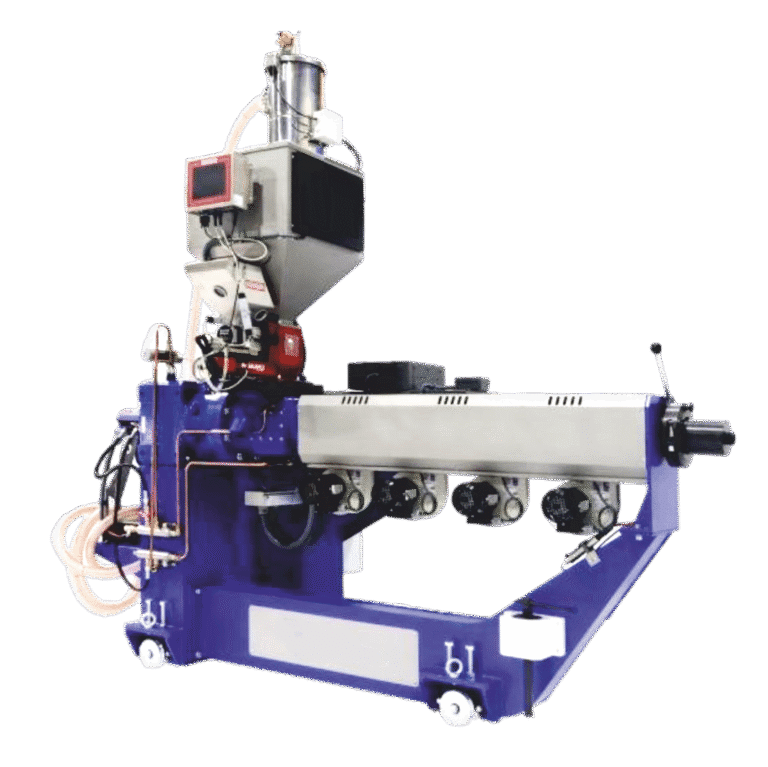

As a leading manufacturer of Cable and wire extruder line machines in India, the latest generation of Supertec Machines’ rubber extrusion lines is engineered to meet the evolving demands of LSZH, HFFR, and XLPE cable extrusion. These advanced systems integrate energy-efficient torque motors that enhance productivity and precision in EV charging cable extrusion lines, polyethylene extrusion lines, and the automation or retrofitting of existing extrusion systems. For users who want to understand what is an extruder line and how it works, the system’s design showcases the complete extrusion process—from material feeding to pressure-controlled shaping through the die. Each machine is equipped with high-torque gearboxes, ensuring superior performance and reliability while processing modern materials.

The screw and barrel geometry has been developed through decades of Supertec Machines’ extensive experience in the extrusion industry and its in-depth understanding of polymer behavior. The extruder features a modular, high-torque helical gearbox, designed to deliver exceptional torque and durability. Depending on specific process requirements, the system is equipped with either a splash-cooling or forced-cooling lubrication setup—ensuring efficient operation, long life, and minimal maintenance.

What is an cable and wire extruder line?

An extruder is a mechanical device used to shape material by forcing it through a mold or die to produce a specific profile. When we talk about what is an extruder, it is a machine that can extrude shapes of constant cross-section and thickness, including both hollow as well as solid sections. Some brittle metals can be extruded very easily through the extruder line.

The extruder can extrude continuous cross-sections of the finished product or semi-continuous cross-sections depending on the sizes and application of the extruded product. In extrusion, the material is forced through a die to form products of various shapes and sizes, such as pipes, sheets, and rods. During the process, the answer to what is an extruder lies in how the extruder’s screw heats and melts the material while pushing it through a hopper inside the extruder. This critical step makes it possible to create a continuous product that can be shaped depending on the required specifications.

How Does an Extruder Work?

The process of extrusion typically involves four main stages: feeding, melting, shaping, and cooling. Let’s take a deeper look at each one:

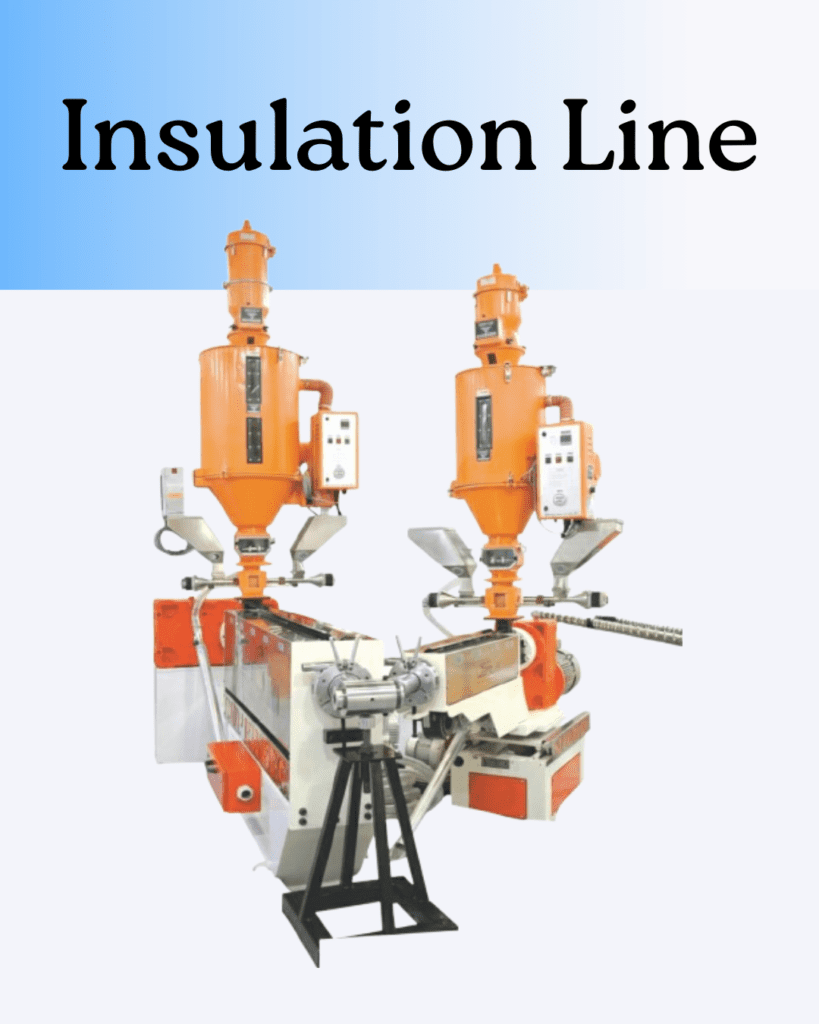

Feeding:

The raw material, usually in the form of pellets, granules, or powders, is fed into the extruder through a hopper. The feed rate, or the speed at which material enters the extruder, is carefully controlled to ensure consistent output. The material, often in the form of granules or powder, is fed into a machine known as an extruder.

Heating and melting:

The material travels through a heated barrel, which contains rotating screws. The screw or screws in the extruder rotate while heating the material. This heating causes the material to melt, turning it into a plastic or fluid state.The friction generated by the screw also helps to break down the material’s structure, aiding in its melting or softening. The screw or screws in the extruder rotate while heating the material. Heating systems are fundamental to bringing the material to the right temperature for melting

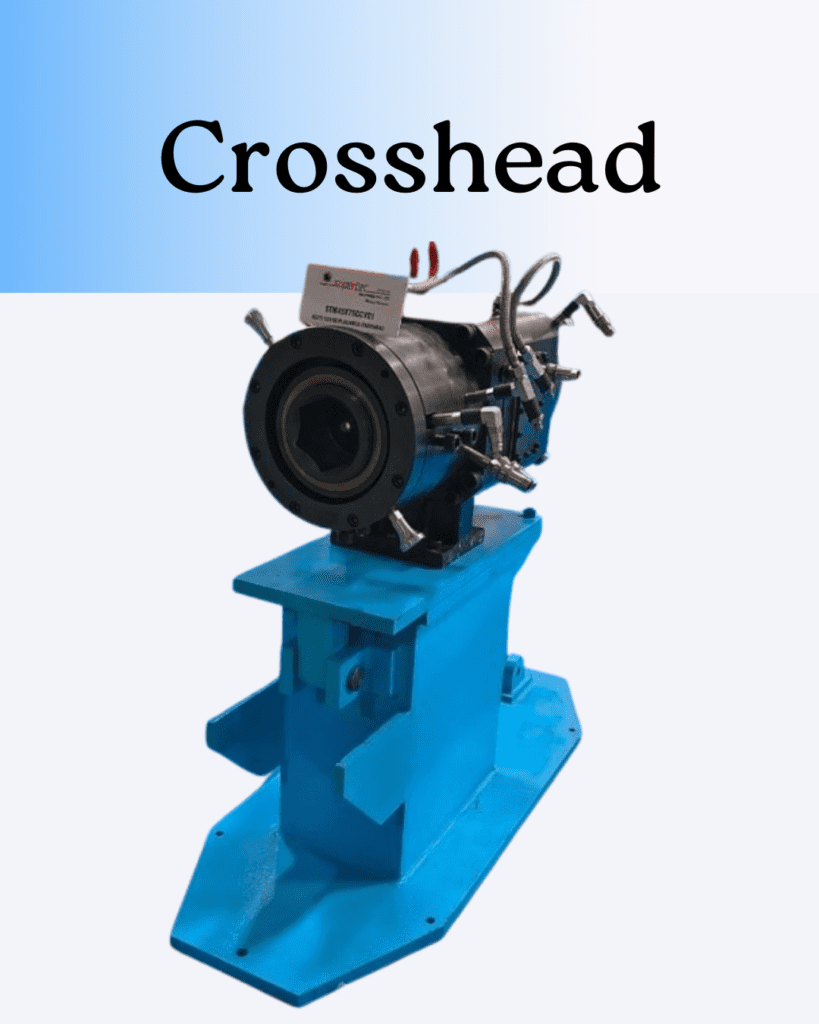

Shaping (Forming):

After the material is sufficiently melted or softened, it is forced through a die – a tool that defines the final shape of the product. The screw or screws continue pushing the molten material through the machine. This pressure allows the material to flow through a mold or die, taking on the required shape. The die can be custom-designed to create an infinite range of profiles, from simple tubes and pipes to more complex shapes like window frames, electrical wiring, or even medical devices.

Cooling:

To maintain its shape and solidify it, the extruded material is rapidly cooled, often using air or water baths. Cooling helps to solidify the material, giving it the required rigidity and durability to maintain its form. Once shaped, the products go through a cooling process that solidifies the material, fixing its shape.

For certain products, additional processes like cutting or stretching may occur as the material cools down to the desired size.

Applications of Extrusion

Extrusion is a versatile process used in many industries to produce a wide range of products. Some of the most common applications of extrusion include:

- Plastic Industry: Manufacturing pipes, sheets, films, profiles, and cables.

- Food Industry: Producing snacks, breakfast cereals, pasta, and other food items.

- Automotive Industry: Creating parts such as seals, gaskets, and trim pieces.

- Medical Field: Making items like catheters, tubes, and specialized medical equipment.

- Construction Industry: Producing building materials like window frames, roofing materials, and flooring.

TYPE OF EXTRUDERS

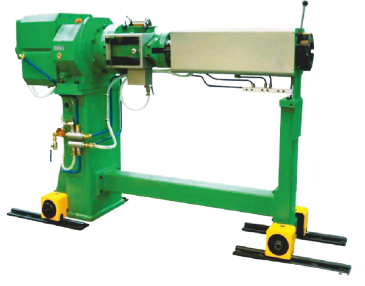

Silicone Extruders

Mechanical Characteristics

- Robust reducer with integrated AC motors.

- Cylinder and endless screw and shirt made of bimetallic material.

- Water cooling in the gearbox, motors, cylinder, endless screw and feed zone

Electrical Equipment

- AC motors are integrated into the gear unit.

- Digital frequency inverter for AC motors.

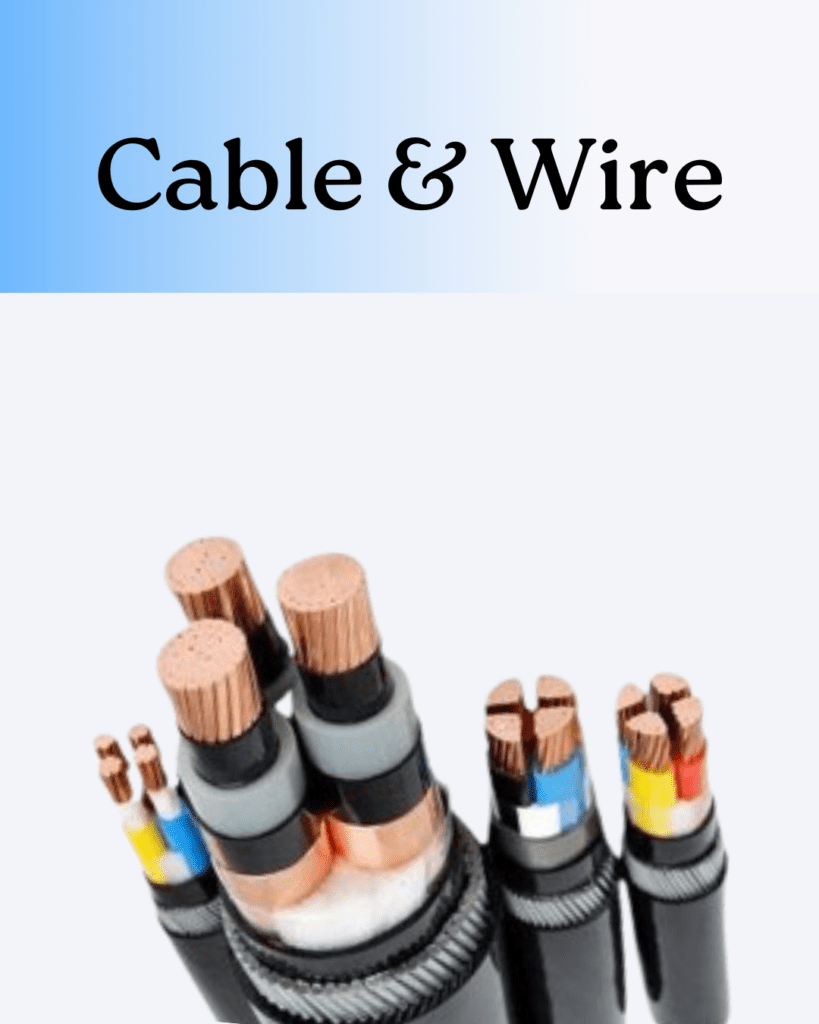

Data cables insulation lines.

Mechanical Characteristics

- Data cables insulation lines.

- Building wires insulation lines.

- Automotive cables insulation lines.

- Combined lines.

- Sheathing lines.

- Tandem filling and sheathing lines.

- Fluorinated products insulation line.

- Silicone insulation lines.

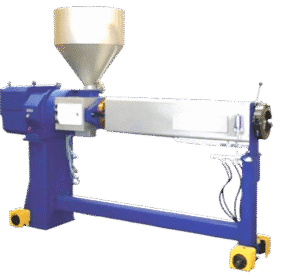

Rubbers Extruders 45 to 175mm

Mechanical Characteristics

- Robust reducer with integrated AC motors.

- Cylinder and endless screw and shirt made of bimetallic material.

- Water cooling in the gearbox, motors, cylinder, endless screw and feed zone

Electrical Equipment

- AC motors are integrated into the gear unit.

- Digital frequency inverter for AC motors.

Request a Quote Today

Reach Us

Location :

Khasra No-205/437, Mahalaxmi Temple, Ballabhgarh-Sohna Rd, near Radha Sowami Ghar, Faridabad, Pali, Haryana 121005

Email :

vishalgupta2902@gmail.com

info@supertecmachines.in

Phone :

+91 8595423093

+91 9654723093